Hi, we are AerogelZone.

We are the international marketing& sales branch of China’s humble and top silica aerogel manufacturer–Namate New Materials Technology Co., Ltd.

We focus on the innovation and cost-effective production of high quality silica aerogel materials like silica aerogel powder/particles, aerogel insulation blankets/panels, battery cell-to-cell aerogel thermal barriers, aerogel new products like aerogel insulation tube shells, etc.

Our aerogel materials are widely applied home and abroad in various fields like oil&gas, petrochemical, power generation, new energy vehicles, building construction, etc.

Hey, Check Our Sample Room and Workshop Now

This video was shot when I was standing in our Xiamen factory sample room.

Here we display most of our silica aerogel materials produced here including silica aerogel blocks/powder/particles, aerogel insulation blankets/panels, battery cell-to-cell thermal barrier (core sheets), and our newly developed aerogel insulation tube shells, etc.

As for some of the displayed aerogel materials, you cannot find them anywhere else in the whole world.

See Our R&D Capability

This video was shot when I was in front of our workshop area.

This workshop’s annual production capacity: 500k square meters of silica aerogel materials, and 1k tons of silica aerogel powder/particles. For normal orders, our lead time 2-3 weeks.

Since early 2024, our new headquarter factory in Chongqing has been normally running. And the production capacity and product quality are now top in China.

We already hold in hand the intricate synthesis techniques and mature and cost-effective mass production techniques of silica aerogel.

This video shows you basically how our silica aerogel is made. Our key technique applied here is called ‘nitrogen-exchange-ethanol supercritical drying’, which is unique and pioneering in the whole world.

Performances of the silica aerogel which is produced with nitrogen-exchange-ethanol supercritical drying are much better than any other current existing drying processes.

China Universities& Research Institutes We Cooperate with

Our Aerogel R&D Fields

Our R&D and Testing Equipment

Quality Assurance of Aerogel Materials

When you receive our aerogel product, the quality inspection report is along inside, and each piece of the product is quality traceable.

We have a strict and complete quality assurance system including quality management standards, processes, tools, QC staff, and inspection instrument and equipment, etc.

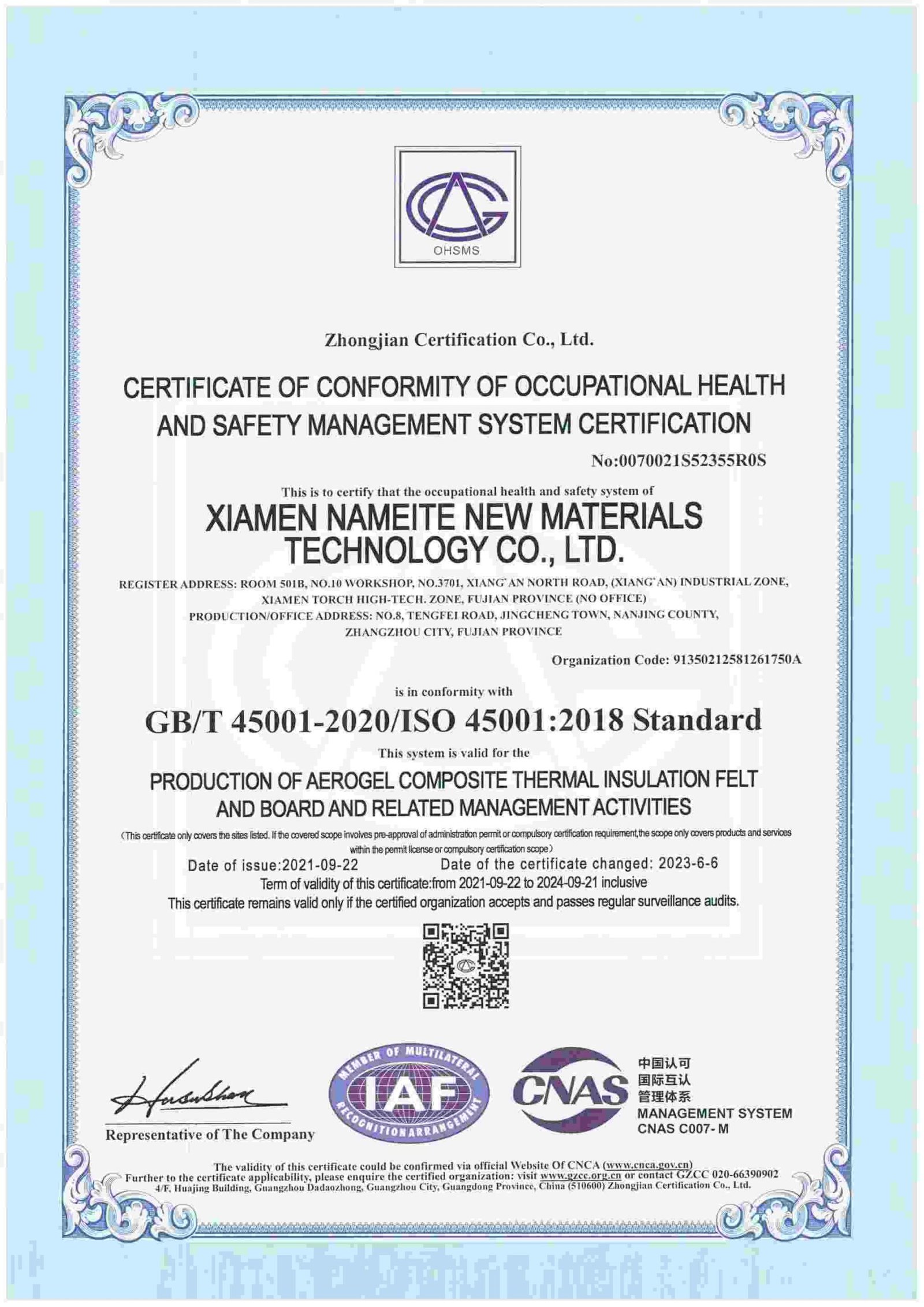

Quality Management Standards We Follow

We’ve been strict in quality management since the very first day of our aerogel career. The quality management system certifications we’ve passed:

Our Quality Management Process

We are strict in quality management throughout the whole process from raw material supplier management to final customer feedback.

Supplier Management

Supplier survey and evaluation

Qualified supplier and backup supplier archiving

Supplier performance evaluation and daily supervision

Material Incoming Process

Incoming material warehousing

Incoming material quality inspection and control

Defective material supplier liability confirmation and solution analysis

Production Process

In-process quality audit

Problem analysis and solution by an internal team

Semi-finished and finished product inspection

Sales Process

Finished product shipment process

Third-party warehousing and final customer market feedback

Problem analysis and solution by an internal team

Our Quality Management Tools

We make full use of the five professional management tools below to maintain our aerogel products’ quality at a high level.

APQP

Advanced Product Quality Planning: we do planning, execution, and control from new product project approval to delivery.

FMEA

Failure Mode and Effects Analysis: we do preventive control of the risks in product design and process development.

SPC

Statistical Process Control: we apply statistical techniques to analyze and control a process or production method.

PPAP

Production Part Approval Process: we do capability analysis and variation control of the product manufacturing process.

MSA

Measurement System Analysis: we do capability analysis and variation control of the whole measurement system.

Our Quality Inspection Equipment

This video was shot when I was in our quality inspection center labs.

In this video, we just show you our key inspection equipment and instrument: high temperature multi-functional load tester, specific surface area and porosity analyzer, and thermal conductivity meter.

There are a variety of quality inspection equipment in our quality inspection center. You can check the below listed ones for reference.

Our Amazing Clients

Why Us

We are committed to delivering quality aerogel materials, professional technical support and thoughtful customer services beyond your expectations.

What Customers Say About Us

Discover what our valued customers have to say about our aerogel solutions and services. We believe that reviews by customers speak louder than whatever we could say about ourselves.

"Amazing, your pre-sales insulation sample solution really attractive to us, and your team so professional. Honestly, we learned a lot and hope we can visit your factory soon."

CEO

"Many thanks for offering a simple solution to test your aerogel powder samples before we send them to end customers. It really works and no customer complaint happens."

SOURCING MANAGER

"Lucky to have you as our business partner. So fast delivery and time difference is never a problem. BTW, we found your aerogel powder and blanket quality better the famous one here."

PURCHASING DIRECTOR

"Thank you very much. We love your customized turnkey solution. Now we don’t have to source materials for our insulation project one by one. That really helps us save a lot."

COO

Frequently Asked Questions

Discover the Power of Aerogel Today

Have more questions about the magical aerogel materials? Contact us now.